In this paper, Mo-Cd compounds obtained by deposition in an ion-plasma installation were considered. For this purpose, a method is used for obtaining coatings with a nanocrystal structure using ion-plasma deposition of metals, followed by deposition on the substrate in the form of island films. Fundamentally new coatings based on molybdenum-cadmium Mo-Cd were obtained. For the first time, mo-Cd synthesis was obtained at a temperature not higher than 100 ° C and was carried out using the thennoflutination melting effect. The channeling effect was used to study the structure of single-cry stal samples using Rutherford backscattering spectroscopy. Based on the analysis of the spectra obtained at different orientations of the ion beam in the channeling directions, it is possible to obtain information about the crystal perfection of the studied sample. From the analysis of the value of the surface peak, which is the result of a direct collision of ions with surface atoms, you can get information about the structure of the surface, for example, about the presence of rearrangements, relaxations and adsorbates on it. The experiments were performed using an x-ray diffractometer, an electron microscope, and a cryogenic unit.

Introduction

The constant growth of computer applications in all spheres of human life causes a great interest of the world economy in the development of integrated circuit technology. The development of such technologies is an extremely topical scientific and technological task, in which a huge flow of investments is directed. The main task at the same time is to reduce the cost of production along with the improvement of consumer characteristics, which include speed and specific energy consumption.

It is known that small metal particles have significantly lower melting points than their volumetric counterparts [1]. Therefore, it can reasonably be assumed that a decrease in the size of small particles can also positively affect the lowering of the thermal threshold of the molybdenum-cadmium formation reaction.

Method of research

Ion-plasma sputtering of metals and their subsequent deposition on the substrate in the form of islet films is the most widely used method of obtaining coatings with a nanocrystalline structure. Island films refer to ultradispersed systems, the surface energy of which is comparable with the volume component. In this connection, particles in an islet film, whose dimensions are less than a certain critical one, may be on the verge separating the solid and liquid state due to so-called thermofluctuation melting [2]. And, if the use of the effect of thermofluctuation melting in the preparation of alloys is already being used [3], then there are no facts of the use of nanoparticles in heterophasic synthesis of compounds, for example, Mo- Cd-based metals.

Urgency of research. The relevance of this work is to obtain fundamentally new coatings, based on Mo-Cd. In this paper, it is proposed to obtain samples with different concentrations. I have studied the literature on this topics, and it can be concluded that the study of this topic did not take place, due to the complexity of the experiment. The difficulty lies in the various melting points, so it is not possible to obtain an alloy of these metals by the traditional method.

The novelty. That is the first time, where it was introduced the synthesis of the Mo-Cd at a temperature not exceeding IOOoC and was carried out using the thermoflutuation melting effect and the results of the investigation of the structure of the coatings are shown below. In this regard, the formulation of research is timely and relevant, and the results - new.

Today scientists all over the world trying to create materials, which will be having such characteristics as: superconductivity, small weight, toughness, etc. Molybdenum and cadmium have absolutely different structures and properties, also they have different temperature of melting. Temperature of melting for Mo is 2890 K and for Cd is 594 K. So we cannot combine them in traditional way, because the temperature of boiling for Cd is 1038 K and its lower then temperature of melting for Mo. I want to arrange an experiment, where I will combine this metals in ion-plasma set and asses its structure and characteristics. But for the first of all, I want to introduce physico-chemical properties of Mo and Cd.

Cadmium is an element of the twelfth group, the fifth period of the periodic system of chemical elements OfMendeleyev, with atomic number 48. Denoted by the symbol Cd (Latin - Cadmium). A simple cadmium material under normal conditions is a mild malleable ductile transition metal of silvery white color. Stable in dry air, in moist on its surface an oxide film is formed, which prevents further oxidation of the metal.

Research result

Table 1 Properties of Cd and Mo

|

Property |

Cd |

Mo |

|

Atomic mass |

112,411 Da |

95,96 Da |

|

Atomic Radius |

154 pm |

139 pm |

|

Melting temperature |

594 K |

2890 |

|

Boiling temperature |

1038 K |

4885 |

|

Lattice structure |

Hexagonal |

Cubic body-centered |

|

Note - compiled by the author |

||

X-ray diffraction analysis

X-ray structural analysis are methods for studying the structure of a substance by the distribution in space and the intensities of the x-ray radiation scattered on the analyzed object. (X-rays - electromagnetic ionizing radiation, occupying the spectral region between gamma and ultraviolet radiation within the wavelengths from 10-12 to 10’5 cm). X-ray diffraction analysis along with neutron diffraction and electron diffraction is a diffraction structural method. It is based on the interaction of X-rays with the electrons of matter, as a result of which X-ray diffraction occurs. X-ray diffraction is the scattering of X-rays by crystals (or molecules of liquids and gases) in which secondary deflected beams of the same wavelength appear as a result of the interaction of the primary X-rays with the electrons of matter from the initial beam of rays. The direction and intensity of the secondary beams depend on the structure of the scattering object. The diffraction pattern depends on the used wavelength of the X-rays and the structure of the object. To study the atomic structure, it is used length equal 1, i.e. the size of the atoms [4]. Waves X-ray diffraction analyzes metals, alloys, minerals, inorganic and organic compounds, polymers, amorphous materials, liquids and gases, molecules of proteins, nucleic acids and etc. This method is most successfully used to establish the atomic structure of crystalline bodies. This is due to the fact that the crystals have a strict periodicity of the structure and represent the nature-created diffraction grating for X-rays.

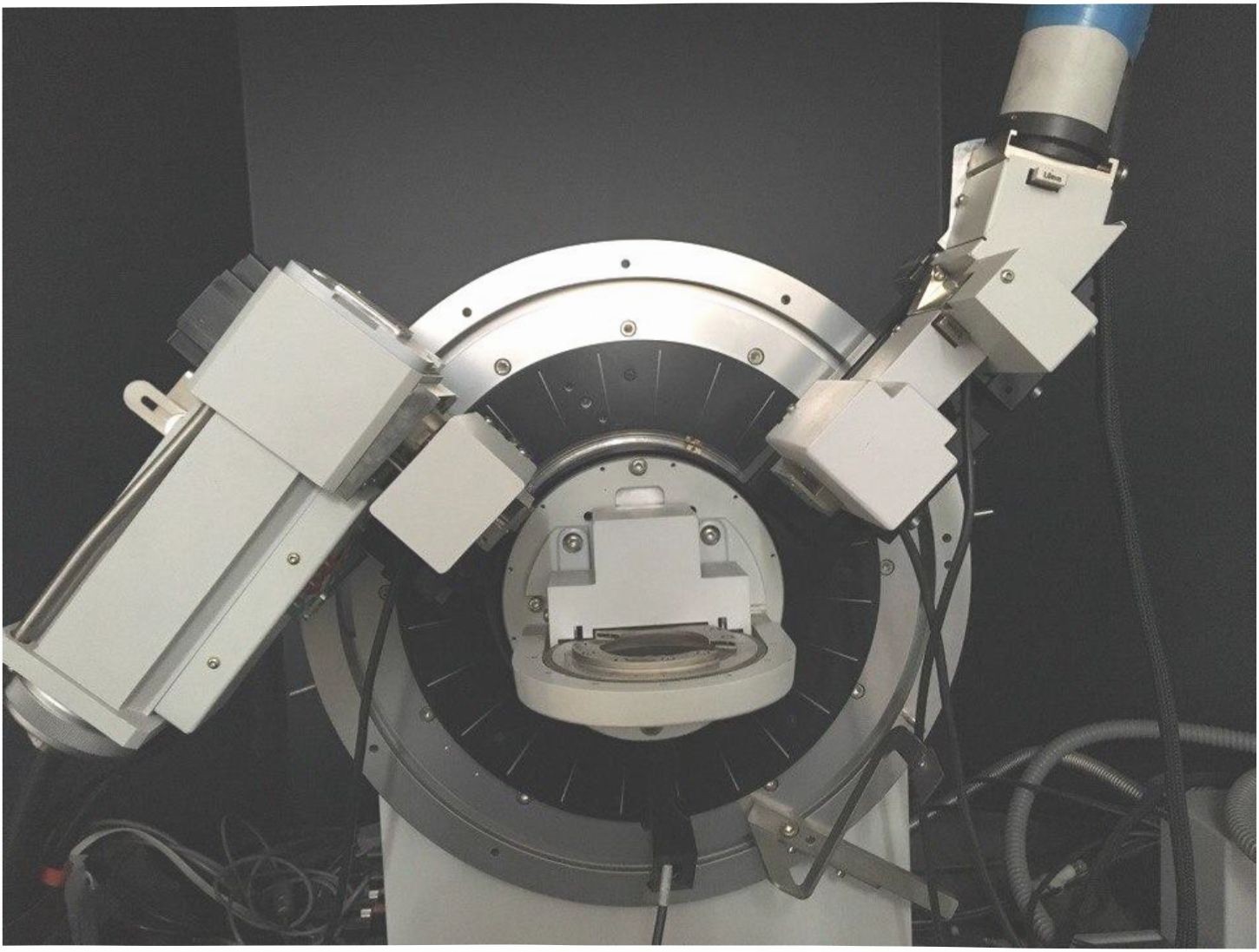

Figure 1 X-ray diffractometer [7]

Electron Microscopy (JEM-2100 (JEOL))

In an electron microscope, instead of light, an electron beam in a vacuum is used to construct the image. The electromagnetic field which is created by electromagnetic coils focusing electrons as «lenses». The image in an electron microscope is observed on a fluorescent screen and photographed. Objects in electron microscopy are in a deep vacuum, so they are subjected to fixation and special treatment.

In addition, they must be very thin, since the flow of electrons is strongly absorbed by the object. In this connection, ultrathin sections with a thickness of 20-50 nm, placed on the thinnest films, are used as objects. The resolution of microscopes is significantly higher than light microscopes and reaches 1.5A (0.15 nm), which allows us to obtain more detailed photography.

Conclusion

The effect of channeling is used to study the structure of single-crystal samples using Rutherford backscattering spectroscopy. The effect is that when the ion beam is oriented along the main directions of symmetry of single crystals, those ions that avoid direct collision with surface atoms can penetrate deep into the crystal to a depth of up to hundreds of nanometers, moving along channels formed by atomic rows [5]. Comparing the spectra obtained by orienting the ion beam along the channeling directions and along directions different from them, one can obtain information on the crystal perfection of the sample under study. From the analysis of the magnitude of the so-called surface peak, which is a consequence of the direct collision of ions with surface atoms, one can obtain information on the structure of the surface, for example, on the presence of reconstructions, relaxations and adsorbates on it.

Schematic diagram of the spectrum ot ions with a mass mi and primary energy Eq scattered from a sample consisting ot a substrate of atoms with a mass of m2 and a film of atoms with a mass m3 of thickness d. For simplicity, both the film and the substrate are considered amorphous to avoid structural effects [8-9].

Cryogenic Test

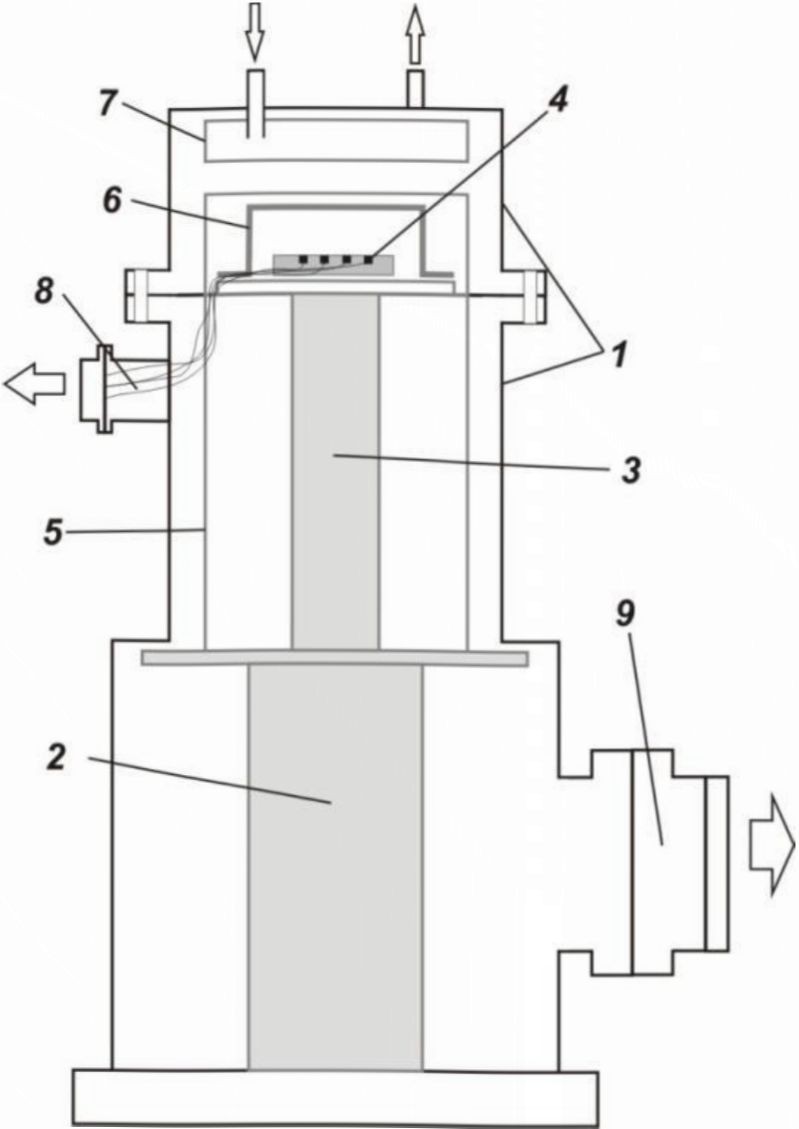

The installation for cryogenic testing of samples consists of a Gifford-McMahon refrigeration machine, a cryogenic oil trap evacuation system and a measuring complex that allows recording the temperature and time dependence of the resistance. Schematic device of the installation for cryogenic testing of samples is shown in Figure 4.

Figure 3 Scheme of cryogenic facility (Note: 1-case, 2-first cooler stage, 3-second cooler stage, 4-meter assembly, 5-thermal screen of the first cooling stage, 6-thermal screen of the second cooling stage, 7-nitrogen caisson, 8-terminals of the measuring assembly, 9- branch pipe leading to the pumping system)

The pumping system used in the chiller is similar to the vacuum system for pumping a magnetron installation for the synthesis of coatings.

The cooling system consists of a casing 1, a two-stage cooling system closed by thermal shields 6, 5, and a measuring assembly 4 located at the end of the second stage of the cooler. To measure the temperature at the measuring assembly, a TBO thermistor of 0.125 1 kQ is used, which has an exponentially increasing resistance as the temperature decreases. The thermistor was calibrated with a number of reference samples of superconductors calibrated at the ISSP of the ChNC of the Russian Academy of Sciences (Chernogolovka, Russia) with critical transitions to the superconducting state at T = 16.5 K, 13.8 K, and 10 K. The thermal screen 5 of the first stage cooling is made of a copper sheet 0.4 mm thick, pasted with polished aluminum foil. The heat shield 6 of the second cooling stage is made in the form of a turning part made of copper with a wall thickness of 1.2 mm. The outer surface of the copper screen of the second stage is polished to the 13th grade Ofcleanliness.

The vacuum system works in the following way: the fore-vacuum pump through the K8 valve pumps out the diffusion pump to the primary vacuum, after which the diffusion pump is heated. When the operating temperature of the diffusion pump (160 ° C) is reached, by using the bypass valve K7, the working chamber is pre-pumped to 2-3 Pa, which is controlled by the lamps Pl and P2. After reaching the necessary vacuum in the working chamber, the valve K7 is closed and the valve K4 opens. Achieving the necessary vacuum in the working chamber is fixed by ionizing lamp P3 (PMI-2). Vacuum system provides pumping of the working chamber to a basic vacuum of 3 * IO'4 Pa. System pumping can be done both in manual and in automatic mode.

References:

- Benlienda S., Guglielmacci J.M.. Gillet M.. Hultman L.. Susgren J.-E. Effect of substrate bias on the protective properties of TiN films grown by reactive magnetron sputtering onto Cu substrates// Appl. Surface Sci.-1989.-Vol.40.-№l-2.-P. 121-128.

- Тулеушев А.Ж.. Володин B.H.. Тулеушев Ю.Ж.. Жаканбаев Е.А. Новое соединение Ta3Pb: получение, структура и свойства. // Ядерная и радиационная физика. Матер. 4-ой Межд. конф.. 15-17 Алматы. 2004г. - с.270-276.

- Wronski C.R.M. The size dependence of the melting point of small particles of tin // Brit. J. Appl. Phys.-1967.-Vol. 18. № 12.-P.1731-1737.

- Белый A.B.. Карпенко Г.Д. Структура и методы формирования износостойких поверхностных слоев. -M.: Машиностроение. 1991.

- Волин Э.М. Ионно-плазменные методы получения износостойких покрытий (Обзор зарубежной литературы за 1979-1983 гг.) // Технология легких сплавов.-№ 10.-1984.

- Hill R.G.. Connia R.. McLeod P. High rate magnetron sputtering// Proc. 7th Int. Vac. Congr. and 3rd Int. Conf. Solid. Surfaces. Vienna.-1977.-Vol.2,P.1583-1586.

- Электронный ресурс - сайт производителя техники JEOL: http://jeolnis.com/products/d_products/jem-2100/index.html.

- Johansson В.0.. Sudgren J.-E.. Hentzell H.T.G.. Karlsson S.-E. Influence of substrate shape on TiN films prepararedby reactive sputtering//Tlrin. Solid. Films.-1984.-Vol.lll.№4.-P.313-322.

- Stowell M.J. The Solid-Liquid Inlerfacial Free Energy of Lead from Supercooling Data // Pliil. Mag.- 1970.-Vol.22. JV2176.-P.l-6.

- Жаканбаев E.A., Тулеушев Ю.Ж. Исследование влияния параметров магнетронного осаждения на сверхпроводящие свойства пленок нитрида ниобия// Тез. 7 межд.конф. «Ядерная и радиационная физика».-Алматы. 2007.-С. 102-104.